Nearly two decades after the first papers describing the relationship between sacrificial anodes and corrosion rates were released, Impressed Current Cathodic Protection (ICCP) systems have been introduced to masonry restoration industry and are becoming a more common part of complete rehabilitation programs. ICCP has proven itself across many applications as a long-term solution to maintaining the condition of existing corroded steel and brings value to building owners by maintaining and extending the service life of embedded steel via electrochemical corrosion mitigation.

Over 18 months, Central Building & Preservation successfully managed and surgically installed a 10,000+ anode ICCP system within the flying buttresses and screen walls of the historic 1925 neo-Gothic skyscraper, Tribune Tower. This non-invasive strategy was chosen in lieu of complete removal and reinstallation of the limestone façade, exposing and then replacing the corroded embedded steel. Securing project feasibility, providing cost savings to the stakeholders, and preserving the well-known architectural features of the building, ICCP will continue to be integrated into masonry restoration in the future.

Central has also utilized Cathodic Protection with the use of sacrificial anodes in concrete restoration projects

Cathodic Protection Gallery

Tradesman splicing an anode to the titanium connecting wire.

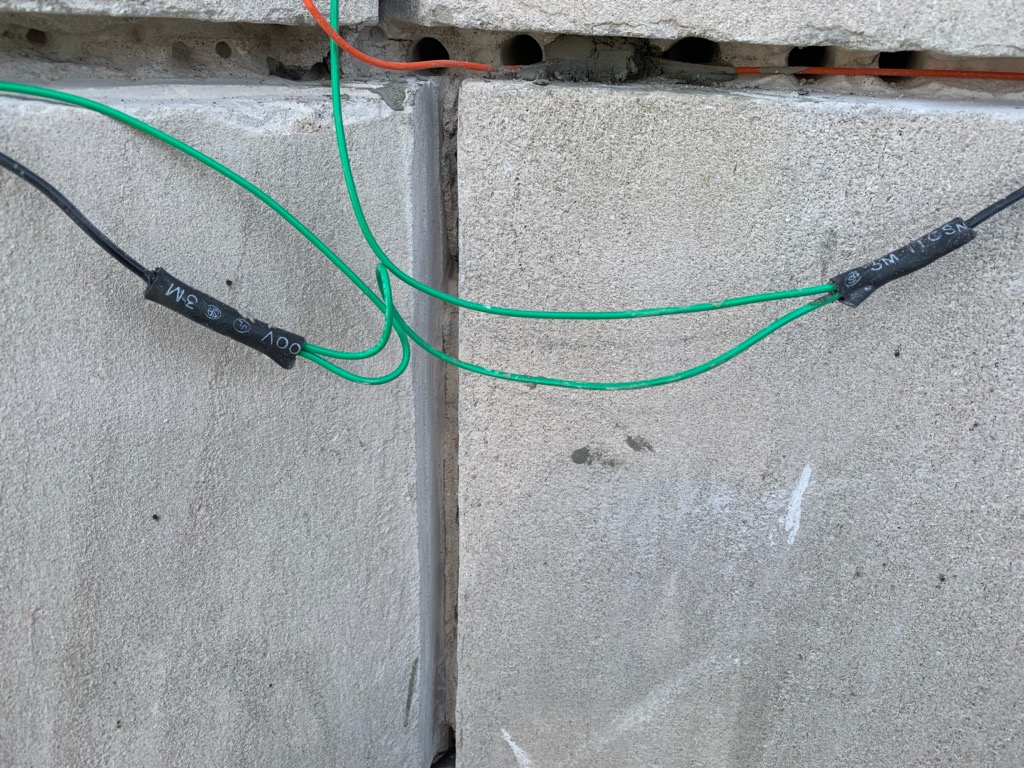

Tradesman splicing an anode to the titanium connecting wire. A sacrificial anode is grouted in to the drilled hole and the black wires bonded to anchors are spliced in to the system.

A sacrificial anode is grouted in to the drilled hole and the black wires bonded to anchors are spliced in to the system. Black wires tack-welded to existing anchors and covered by conductive epoxy are spliced in to the system.

Black wires tack-welded to existing anchors and covered by conductive epoxy are spliced in to the system. A sacrificial galvanic anode is connected to rebar prior to concrete patching.

A sacrificial galvanic anode is connected to rebar prior to concrete patching. During extensive stone restoration, CP wiring remains exposed until the system is tested and certified.

During extensive stone restoration, CP wiring remains exposed until the system is tested and certified.